Non-intrusive machine assets monitoring

Non-intrusive machine assets monitoring Within a production line, a lot of data can be monitored. This data is often relative to an unique part, which creates a dataset of discrete values only based on assembly process.When a defect occurs, its root cause may be...

Zero defects manufacturing

Zero defects manufacturing Zero Defects Paradigm aims at guaranteeing excellence in all the steps of the production process, from concept and design to manufacturing and mounting. Ideko es participating in three important European projects that apply digital...

Presentation of Qu4lity Project

Presentation of Qu4lity Project The European QU4LITY project aims to create and subsequently validate, in a measurable and replicable way, a Zero-Defect Manufacturing (ZDM) model, aimed in particular at SMEs. The validation of the model will take place through the...

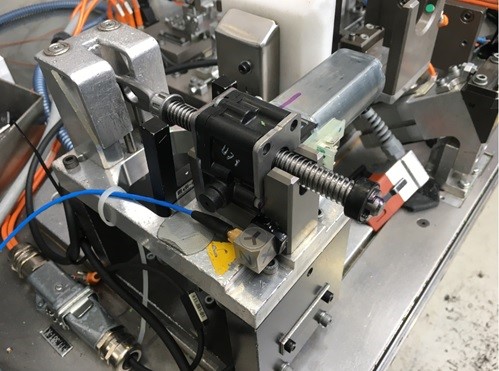

QU4LITY enables the Interoperability and ZDM at MONDRAGON

QU4LITY enables the Interoperability and ZDM at MONDRAGON To make the new industry paradigm (Industry 4.0) a success, companies need to implement more complex, interoperable, reconfigurable and responsive systems for their products and services in a quite natural...

QU4LITY in APMS and CIRP International Conferences

During the last year two research papers dedicated to QU4LITY project were presented at important conferences APM and CIRP CMS during 2020/21. Researchers from SINTEF Manufacturing participated with multiple research achievements of QU4LITY project and were highlighted and disseminated via these conferences.

Recent Comments