Nemak Assistant Systems in Production

Nemak Trial: Zero Defect Production

New Nemak Assistant System Opportunities

New concepts for Nemak Assistant Systems

Data-Driven Digital Process Challenges

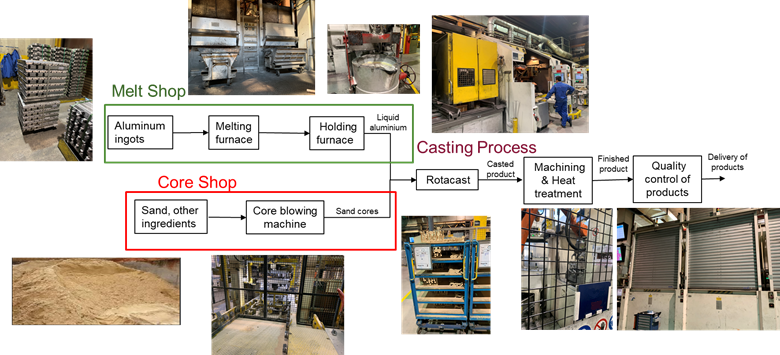

In the Nemak Pilot first concepts were elaborated to assist different human actors involved in Nemak casting processes directly or indirectly through data-based support applications that are called Assistant Systems. Such actors can be managers who need data about KPIs, supervisors who need data about the status of production processes or operators who need data to optimise their machines. It was elaborated how the achievements of the previous business processes can be exploited to support such actors through Nemak Assistant Systems that provide user-friendly interfaces and provide big data based support in daily working tasks.

Big Data Business Process Value

Results of this task brought Nemak an overview about how they can exploit the brownfield transformation and data analysis/simulations models to support their human actors involved in casting processes. As Nemak aims to stay a coveted and modern employer on the specialist’s market, it aims at providing a good working environment with new technology that brings a real accepted value in the daily work of actors involved in Nemak’s casting processes. Results gave Nemak a better overview of opportunities which increased the consciousness for big data (exploitation), which also had an impact on their future strategical movements in exploiting Industry 4.0 for themselves but also for Europe’s casting industry in general.

During BOOST 4.0 several concepts for potential Nemak Assistant Systems in production have been elaborated which has strengthened the awareness for Big Data analysis and the exploitation potential towards every production related branch and leaf inside the Nemak foundry in Linz, Austria.

The following list of Nemak NORIS Assistant Systems in production concepts was elaborated:

- DMC Scanner Assistant System

- Automated Defect Report Assistant System

- CT image re-evaluation Assistant System

- ESI big data Hybrid Twin Assistant System

Observations & Lessons Learned

Overall results of this task have shown that humans involved in the casting processes will get in contact with more and more data-based applications. Companies are now beginning to see the potential behind the use of data, which will lead to vacancies for data-related jobs in the near future. Universities are called upon to prepare students for these coming industrial challenges, and staff also need to be trained in this area, which will generate a demand for training workshops.

Replication Potential

The elaborated concepts for Nemak assistant systems in production were customized for challenges within Nemak. However, similar challenges are faced also by other companies in the light metal casting domain so that learned lessons should be transferable also to such companies. Some assistant systems as the ESI big data Hybrid Twin are based on software that is already widely used and established in the casting industry which is a promising indicator for a good replication potential.

Nemak Linz GmbH

Linz | Austria

Pilot Partners

Standards used

-

Nemak internal Standards for ICT

-

Infrastructures

Big Data Platforms & Tools

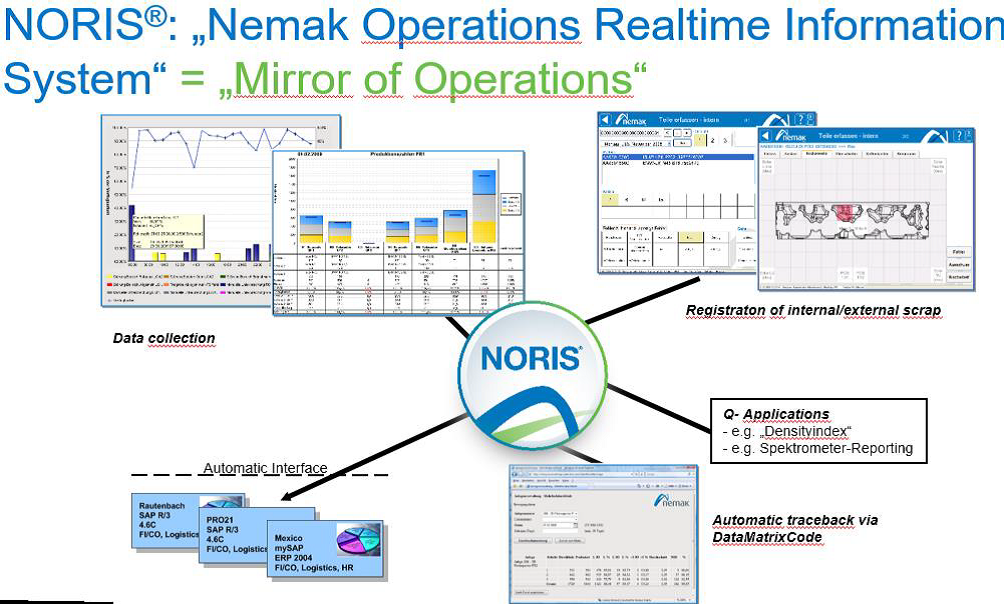

- Nemak Operations Realtime

- Information System (NORIS)

Big Data Characterization

Data types

– not applicable –

Data velocity

– not applicable –

Number of sources

– not applicable –

Open data

– not applicable –

Implementation Assessment

![]()

![]()

![]()

Technical feasibility

Nemak Assistant Systems in production are customized applications for data exploitation in Nemak. The technical feasibility depends on the application, but in the majority of cases it can be realized without complex problems.

![]()

![]()

![]()

Economic feasibility

Nemak Assistant Systems cover a wide range of applications. The economic feasibility is based on the implementation complexity or costs for licenses and is use case dependent.

![]()

![]()

![]()

Replication potential

Nemak Assistant Systems are partly based on generic software as the ESI Hybrid Twin approach. Such systems are reconfigurable and replicable.