Cooperative multi-plant turbine production with predictive quality chains

General Information

Challenge, Value & Description

Performance, Access & Contact

1 – General Information

Partners

Sectors addressed

Application categories covered

Lifecycle level covered

Digital Engineering

Planning & Commissioning

Smart Production & Operations

Smart Maintenance

Customer Service

Circularity

Via I° Maggio, 99, 10040 Rivalta di Torino TO, Italia

Geographical Scope

- Europe

- Southern Europe (Italy, Spain, Portugal, Greece)

2 – Challenge, Value & Description

Challenge

In the RE4DY Project, the EU Green Deal is driving major changes in the aeronautical industry, pushing for innovative jet engine designs to meet strict emission reduction targets. Avio Aero, along with other European leaders and supported by HE Cluster 4 and 5, is leading efforts to develop sustainable solutions for the mobility sector. However, these new engine architectures introduce greater manufacturing complexity, involving novel materials, intricate geometries, stricter quality requirements, and distributed production across multiple sites or partners.

As regional jets—produced in large volumes—adopt next-generation engines, and with air traffic expected to rebound to pre-COVID levels, the pressure on manufacturing quality and waste reduction intensifies. To meet environmental goals, it is essential that production processes remain sustainable and resilient while faithfully translating advanced designs into real-world products.

The key ambition of this pilot initiative is to enable near real-time predictive quality control across distributed, multi-plant aeronautical manufacturing processes.

Value

The pilot gathers data from various manufacturing and enterprise assets—such as CNC machines, inspection stations, and ERP systems—with the aim of developing localized Digital Twins.

These Digital Twins are trained using both internal and external data sources to enhance predictive capabilities. By utilizing open connectors based on IDSA standards, data is shared within a secure data space, facilitating collaboration across plants and the extended supply chain. This exchange allows, for instance, OEMs to access anonymized data from the pilot site and, in return, provide insights from other customers or materials.

These enriched datasets strengthen local Cognitive Digital Twins, enabling advanced analytics and foresight. As a result, new predictive business processes can emerge, such as automatically generating ERP tasks when a quality issue is forecasted, prompting engineers to proactively address potential defects.

Description

Data Value Chain Description

Infraestructure Elements

- IoT gateways / hub

- Private Cloud

Platforms & Tools used

Acquisition: Avio Aero AWS Cloud + ALIDA Cloud Platform

Analysis: ALIDA Cloud platform + Avio Aero’s AWS Virtual Private Cloud (VPC)

Preparation: ALIDA Cloud platform + AWS + S3 EDM (Electric Discharge Machine)

Storage: AWS Cloud

Usage: ALIDA Cloud platform + Smart Vision Suite (Typescript, NextJS, React, TailwindCSS, Konva, Postgres, Prisma ORM, KeyCloak and NextAuthJS)

3 – Performance, Access & Contact Info

Performance

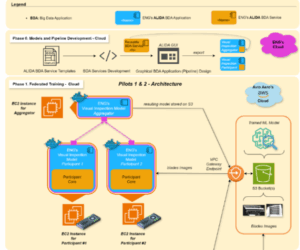

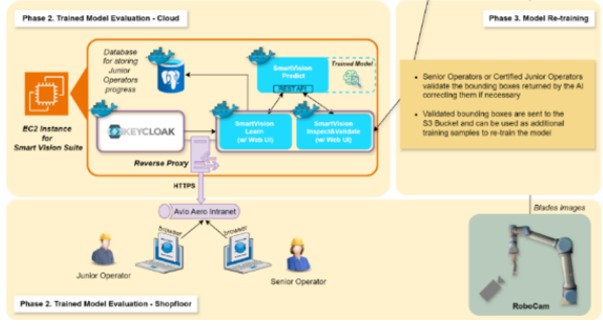

The deployment architecture for Pilots 1, 2, and 3 was successfully defined within Avio Aero’s AWS Virtual Private Cloud (VPC), in accordance with cybersecurity guidelines. Each component was mapped to the appropriate AWS services, with logical connections established to represent different Avio Aero plants. Data from machines is collected and stored in AWS S3, organized by plant for efficient access and processing.

Pilot 1 and 2 focused on two key performance indicators (KPIs). The first KPI—reducing quality control time—showed strong results. By integrating a RoboCam system and an AI algorithm for defect detection, the inspection process time was reduced from its manual baseline to just 9 minutes. This marks a 44% reduction, far exceeding the initial goal of a 10% improvement.

The second KPI—ensuring the AI can detect defects as accurately as human operators—is still in progress. The algorithm is currently being trained with annotated images, and future evaluations will compare its defect recognition results with those of human inspectors.

Pilot 3 adopted a similar infrastructure setup, with secure and logical connectivity between plants and centralized data storage. Overall, the pilots demonstrate significant performance improvements and validate the potential of AI to streamline quality control in aerospace manufacturing.

Lessons Learned & Observations

The Pilot led by Avio Aero offered valuable insights into the application of Big Data and AI/ML technologies for visual inspection in aerospace manufacturing. A major achievement was the successful deployment of the ALIDA BDA and Smart Vision systems, utilizing federated learning and AWS cloud services to enhance the end-to-end lifecycle of manufacturing assets—from design to deployment. This confirmed the potential of cloud-based AI infrastructure in supporting scalable, secure, and efficient operations.

A key lesson learned was the critical importance of data quality. Accurate defect detection relies on high-quality, well-annotated image datasets and relevant process parameters, such as those from EDM machines. Continuous data collection, annotation, and validation are essential for maintaining and improving AI model performance.

Cybersecurity was another significant focus, highlighting the need for strong data protection measures in environments where sensitive operational data is shared and processed across systems.

The project also emphasized the value of continuous learning. Regular re-training of AI models with validated data ensures that systems remain accurate and adaptable to changing manufacturing conditions.

Ultimately, the pilot underscored that successful innovation requires more than just advanced technology—it depends on coordinated teamwork, ongoing data quality improvements, and secure, scalable infrastructure. These lessons will guide future efforts to enhance predictive capabilities and operational efficiency in aerospace manufacturing.

Replication Potential & Feasibility Assessment

The pilots conducted by Avio Aero demonstrate strong replication potential, particularly for organizations operating in industrial or aerospace manufacturing environments. The cloud-based deployment on AWS, including the use of Virtual Private Clouds (VPCs) and S3 storage, provides a secure and scalable architecture that can be adapted across multiple plant locations or even replicated in other companies with similar infrastructure.

One of the key enablers for replication is the measurable performance improvement achieved—specifically, a 44% reduction in inspection time using RoboCam and AI-based defect detection. This significantly exceeds the initial 10% improvement target, offering a strong business case for adoption elsewhere.

The approach is also strengthened by standardized data handling and adherence to cybersecurity guidelines, making it suitable for broader industrial applications where data protection is critical. The use of logical plant separation within a single VPC simplifies centralized management across multiple facilities.

Moreover, the AI models being developed can be retrained or adapted for other parts, machines, or production lines, enhancing reusability. However, successful replication will require consistent image data quality, proper annotation, and investment in integration hardware like cameras. It will also depend on change management and training for operational teams.

Overall, the pilots present a replicable, scalable, and secure model for improving quality control through AI, with clear potential to extend across different sites and industrial sectors.