Closed loop ZDM Data Space (SM4RTENANCE)

General Information

Challenge, Value & Description

Performance, Access & Contact

1 – General Information

Partners

Sectors addressed

- aerospace_defense

- automated_manufacturing

- automotive

- environmental_green

- machinery_equipment

Application categories covered

Boroa, bizkaia, spain

Geographical Scope

- Worldwide

- Europe

- Southern Europe (Italy, Spain, Portugal, Greece)

Lifecycle level covered

Digital Engineering

Planning & Commissioning

Smart Production & Operations

Smart Maintenance

Customer Service

Circularity

2 – Challenge, Value & Description

Challenge

Ensuring seamless data sharing across systems, platforms, and companies (TRIMEK, DATAPIXEL, UNIMETRIK, Client) while keeping metrology-related data secure, trusted, and compliant with industry standards. Currently, data transferring is manual and traditional, often done via email, highly individualized per client, and disorganized. This lack of structure leads to inefficiencies and potential security risks. To address these challenges, a use case is being developed to implement data traceability and security, ensuring a more automated, structured, and reliable data exchange process that enhances efficiency, compliance, and trust across all stakeholders.

Value

A connected metrology data space with enhanced efficiency through the integration of digital twins and secure data exchange, enabling proactive maintenance, zero-defect metrology production and effective data management, transferring and monitoring, benefiting Innovalia Metrology and its clients through interoperability, trust and innovation.

Description

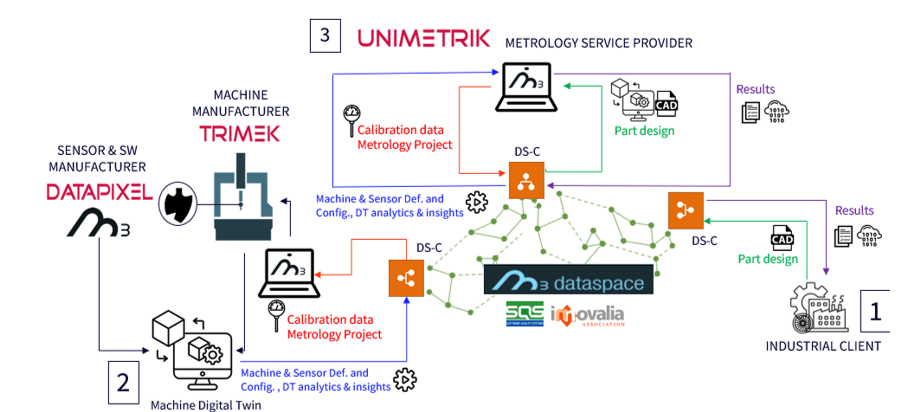

Data is grouped into Machine, Product and Metrology/Calibration data, with all actors as both providers & consumers.

Exchange sequence: The Client buys a CMM from TRIMEK, hires UNIMETRIK for Calibration, and shares Machine configuration data. TRIMEK provides Machine definition data, DATAPIXEL supplies sensor definition data, and with this, UNIMETRIK delivers calibration outputs (Machine Compensation File and Verification Report) for the Client.

Exchange sequence: The Client buys a CMM from TRIMEK, hires UNIMETRIK for Calibration, and shares Machine configuration data. TRIMEK provides Machine definition data, DATAPIXEL supplies sensor definition data, and with this, UNIMETRIK delivers calibration outputs (Machine Compensation File and Verification Report) for the Client.

Exchange sequence: The Client hires UNIMETRIK for the measurement service of one of its manufactured parts. To perform this, UNIMETRIK requires the configuration and definition data of the machine and scanner from TRIMEK and DATAPIXEL to generate the correct measurement inspection program. This program is then executed on the machine to ensure accurate measurements. After the measurement process, UNIMETRIK analyzes the collected data and shares the results with the Client, providing a detailed report on the part’s compliance with specifications and quality standards.

Data Value Chain Description

Infraestructure Elements

- IoT gateways / hub

- Private Cloud

- PLC / Industrial PC

- Data Centre

- Field Devices

Platforms & Tools used

Acquisition: not applicable

Analysis: M3 software for metrology data capture and analysis

Preparation: not applicable

Storage: not applicable

Usage: not applicable

Sharing: D-spacer

Destruction: not applicable

Other platforms & tools: Metrinet tool by Unimetrik for Inventory of equipment.

3 – Performance, Access & Contact Info

Performance

The deployment of the Trimek, Unimetrik, and Datapixel data space, implemented by SQS, has been successful and has met the requirements for data transfer among parties (including the industrial client) for the calibration sequence of a metrology machine (CMM) sold to a client. The deployed infrastructure has been tested for this potential sequence and proven to be functional and operational, enabling secure and efficient data management, as well as facilitating the uploading and sharing of metrology-related data within the ecosystem. Additionally, it has successfully integrated various connectors, allowing dynamic interactions between participants and data sources. Prior to the SMARTENANCE project, Innovalia Metrology companies did not utilize a data space for data exchange, either internally or in interactions with external industrial customers. The pilot is still under development for implementing additional data exchange sequences related to regular operations and interactions among these companies, and the backend/frontend of the D-spacer is being improved in terms of user experience and management. Interoperability tests have been conducted between the connectors of the data space deployment implemented by SQS for Trimek, Unimetrik, and Datapixel, and the connectors deployed by other SM4RTENANCE partner. These tests confirmed that the connectors from separate data spaces are able to interact seamlessly, verifying the successful integration of the systems.

Lessons Learned & Observations

The pilot is still in progress, and several valuable lessons have emerged. To enable the required functionalities, extensive testing and validation of the Trimek, Unimetrik, and Datapixel connectors was carried out to ensure compliance with the Proof of Concept (PoC) and guarantee seamless data uploading, sharing, and exchange. Cross-functional collaboration between the teams managing security, architecture, and data management has been crucial for aligning and securing all components and systems. This collaborative effort, combined with rigorous testing, has optimized the infrastructure for efficient data exchange, improving collaboration, security, and overall efficiency. The deployed infrastructure, implemented by SQS, has successfully supported secure data management, interoperability, and smooth data sharing across the ecosystem, integrating various connectors for dynamic interactions among participants.

Replication Potential & Feasibility Assessment

The pilot, a metrology data space, has significant replication potential across various sectors in the manufacturing industry, such as automotive, aerospace, electronics, and machinery manufacturing. Additionally, the approach to interoperability and communication between data spaces offers scalability and adaptability, allowing it to be extended to different companies, industries, and geographical regions while ensuring easy integration with existing manufacturing systems. The inclusion of Digital Twin technology further enables its application in various asset management use cases. The technical feasibility of replication relies on a scalable architecture, integration with existing systems, advanced data security, and automation and analytics, all of which ensure efficient and secure data exchange across organizations.