Smart Production Planning

Piacenza Trial: Textile pilot – Large Scale & On-site Trial

%

Increasement of Machine

%

More Productivity

%

Set-up’s percentage impact on production

Data-Driven Digital Process Challenges

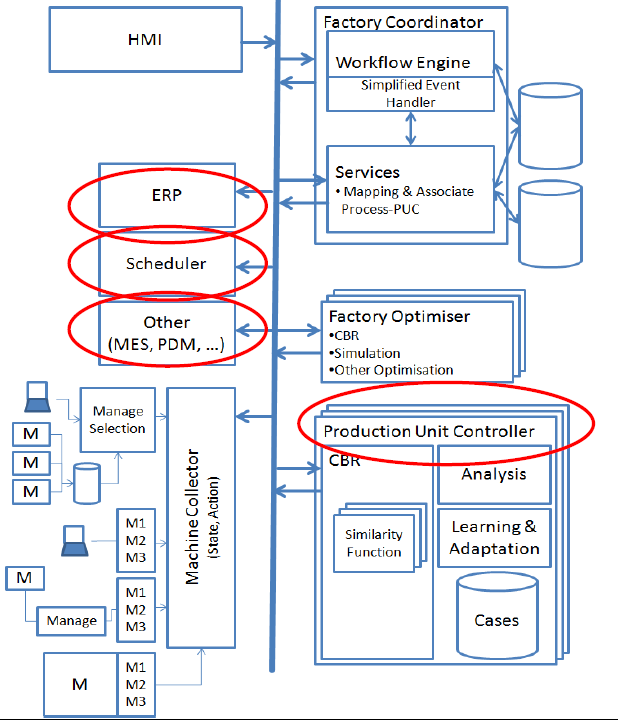

Production planning optimization is a major requirement in industrial sector. The imperative need to optimize the production processes entails the requirement for deeper understanding of production processes and of the available data in order to provide an advanced solution that provides a production plan that maximizes the machines’ usage and minimizes setup times with respect to business aspects such as orders’ priorities and deadlines.

Big Data Business Process Value

The Piacenza Smart Production Planning trial considers a main business processes for implementation:

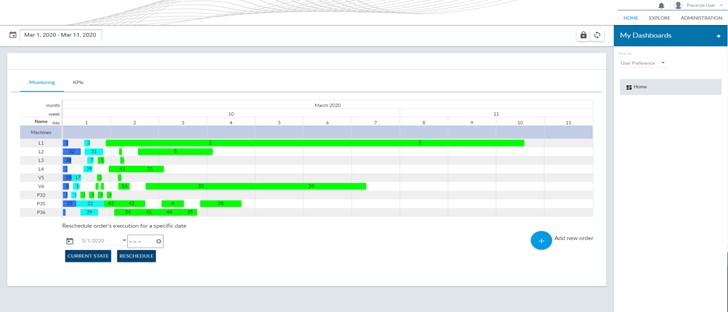

Planning Optimization for Weaving Process: This process has developed a system capable of rapid production rescheduling based on the available data of customers’ orders, current production status and machines. The user is able to add new orders and create a new optimize rescheduling available as a Gantt chart in the corresponding web interface. Furthermore, the user is able to create simulations and check the feasibility of the produced plan by using a simulation tool that supports this business process as well.

Large Scale Trial Performance Results

The Piacenza trial has allowed the implementation of an optimized production planning by utilizing genetic algorithms. The genetic algorithms are widely used for scheduling optimization however one of their main disadvantages is the high computational complexity, that results in big delays in execution time. To tackle this, each chromosome (a proposed solution to the problem) in the population is treated separately, in a multi-processing manner. The calculation of the fitness values and the decoding of the chromosome is specific to each chromosome, so it can happen independently. This parallelization approach boosts the execution time of the solution. However, even though this technique saves a reasonable amount of execution time, scaling up the amount of input (orders, machines) consumes a lot of resources inevitably. This is again tackled, by utilizing an asynchronous job queue, so that the entire algorithm can be executed in the background, without delaying the rest of the functionalities of the platform. The aforementioned techniques enable the rescheduling process to take from some seconds to a few minutes in order to be completed, with respect to the dataset size. Furthermore, CERTH framework provides various technologies for effective usage of large amount of data as Spark for data pre-processing, MongoDB for storage and ChartJS and D3JS for data visualizations.

Observations & Lessons Learned

Using an optimizer for the scheduling plan of the production enhances the collected KPIs, however there is potential in further optimization by involving further processes and not only the weaving one. Furthermore, more data from the production configuration can result into better optimization but require more complex calculations and computational resources. Increased constraints in the plan may result to resource intensive and time-consuming optimization process. Finally, we have defined that the format and content of the production data must be consistent across all the stages of distribution, in order to ensure proper functionality of the optimization tool.

Replication Potential

The approach even as a complete solution or even as separate algorithms can be replicated to other similar processes that requires planning optimization.

Piacenza is in Pollone (Biella)

Piedmont – ITALY

Pilot Partners

Standards used

- eBIZ TCF

Big Data Platforms & Tools

- CERTH BD Cognitive Platform Cloud

- Atlantis DSS

- Visual Components Simulation Tool

Big Data Characterization

Data Velocity

- Machine Data

- Processes Data

- Data related to Production Orders

- Simulation Data

All data are exported on CSV format

- ERP Data

- Data from PLCs

- MES data

- Simulation Data exported by Visual Component Instance

- Scheduling Data by CERTH Planning tool

User input for new orders or for setting priorities for planning to DSS

Implementation Assessment

![]()

![]()

![]()

Technical feasibility

The Smart Planning Solution is available to end-users as a complete web-based platform, exploiting the different dt sources available in textile production.