Samsoftware

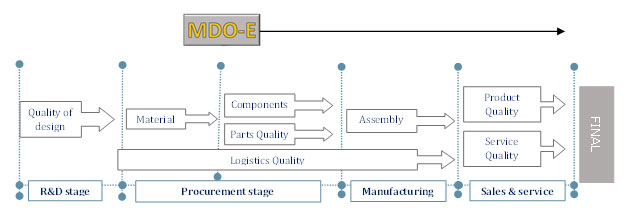

MDO-E: Manufacturing Digital Ontology -Editor

Whirlpool/Lodz Dryer Plant

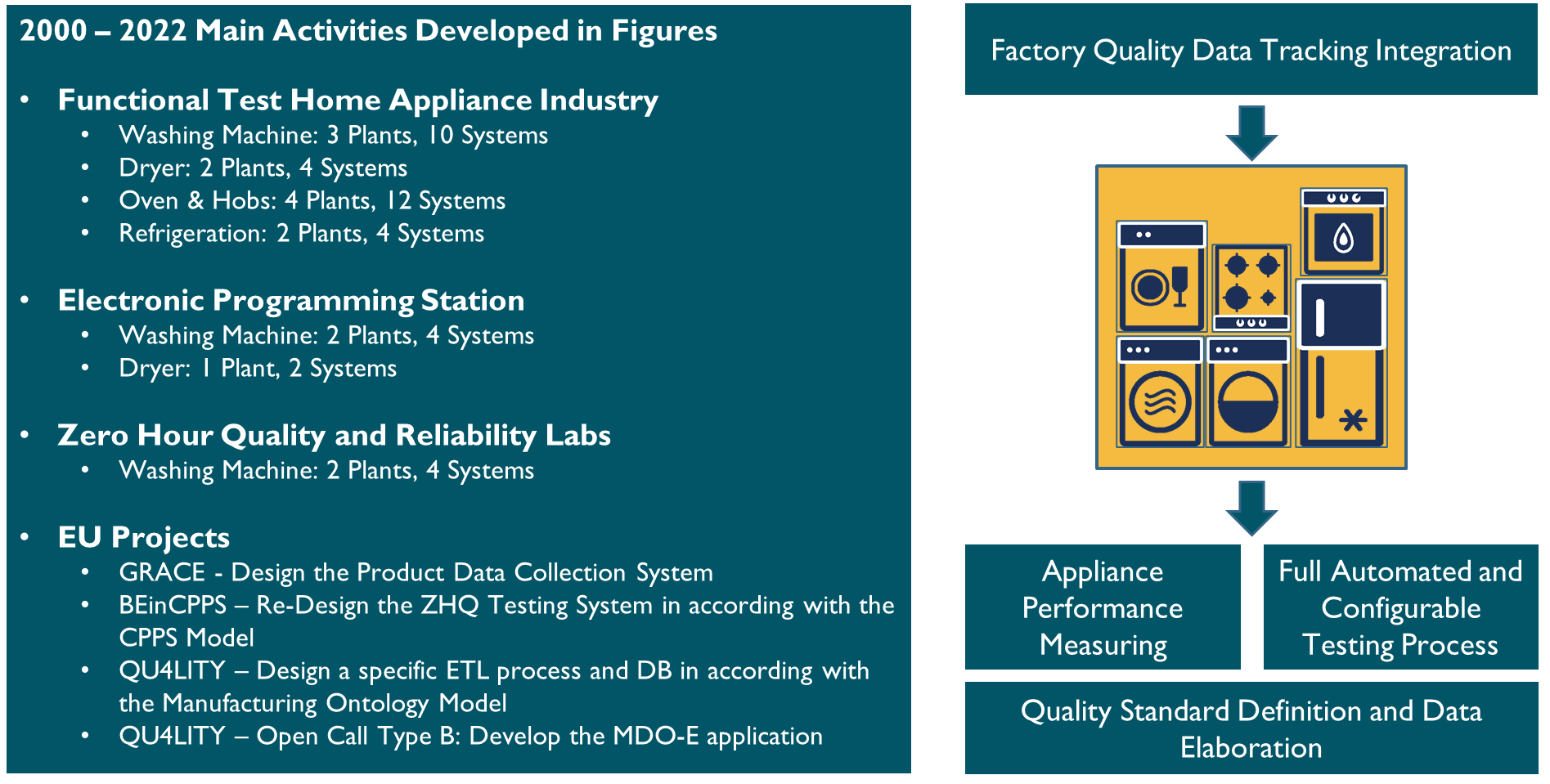

Stefano Preda and Marco Bottinelli are SW Engineer developers, for PC and PLC applications for over 20 years. Specialized in the manufacturing home appliance industries, in particular in the development of systems for the quality control of the final product and production processes. In the 2017 they founded SAM-Software, joining experience and skills in a common company vision. There are three pillars that characterize the company: Standardization of the SW applications, Innovation of the processes and services offered and Vertical integration of applications from the Shopfloor to the MES. Sam-Software has had the opportunity to collaborate in European projects as a provider of service and systems: GRACE, BEinCPPS, QU4LITY and I4Q. This has enriched the company of new technologies and skills.

Process Challenges

Integration of the modelling of the Final Product, based on the Functional Analysis and its Mfg Production Process, is the way to provide an important and crucial tool for elaborating new methodologies for Mfg processes and Quality optimization, in order to guarantee a true Zero Defects Manufacturing, and to create the elements to design the Equipment able to support the main elements of the Autonomous Maintenance for reducing as much as possible the risk of unexpected production stopping or deviation in performances.

Process Value

The MDO-E application is essentially based in the development of a SW suite able of integrating several Mfg and Final Product key elements:

- Definition of a representative ontological model of a manufacturing process,

- Editing of the ontological model in order to characterize and design a production process,

- Development of a functional product model integrated in the manufacturing process in according with the MPFQ scheme developed in the GRACE project,

- Graphic Editor for the development of the functional product model,

- Integration, in according to the MPFQ scheme of quality attributes, in order to define how process and product controls must be developed, and what are the measures to be performed.

Using the MDO-E application the designer has the opportunity to elaborate a production process, where are integrated in a unique vision the 4 key elements that are part of the Mfg system:

- Component,

- Model of Final Product,

- Operation & Equipment,

- Quality.

SAM-Software Activities

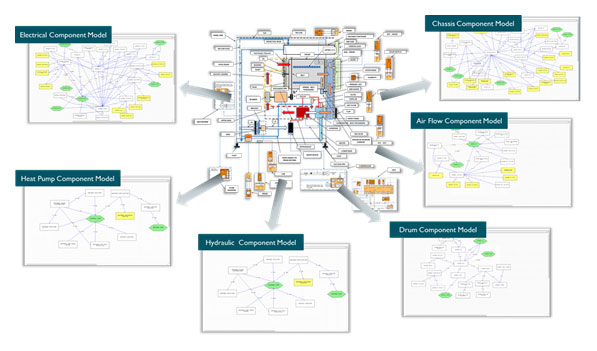

Dryer Functional Model Developed by MDO-E Application

Experiment Performance

The impact of the MDO-E application in the design phases of the quality and manufacturing processes of finished products can be summarized in the following three points:

1) Functional modelling of a finished product. This involves an analysis of how the elements (components) are aggregated or assembled. Understanding how a function is generated in a manufacturing process means to analyse the critical issues, which is the most appropriate resource to use for the assembly, and which are the physical, direct or indirect measures that are aggregable to it.

2) Impact on process KPIs. A correct design of the production flows allows to set the operational design by having a perfect knowledge of the critical elements involved as components and/or the operations. If a component has corrected assembled, even it is work properly by itself, it can influence negatively the global functioning of final product

3) MDO-E integrates in the process of modelling the correlation with all the attributes of quality that the consumer perceives, both through the functions and through the process measures related to them

Value chain

Observations & Lessons learnt

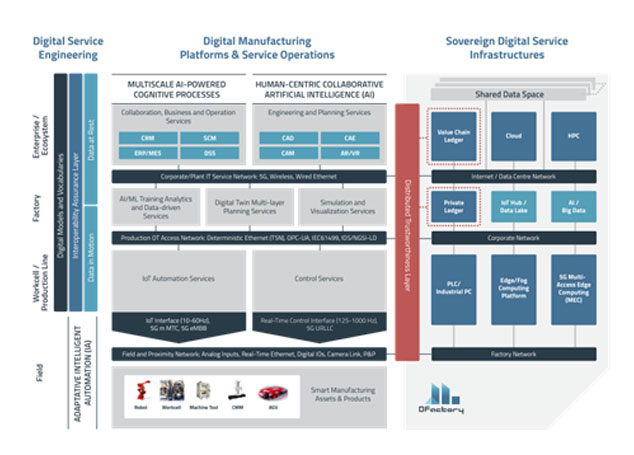

Some considerations can be done about the MDO-E project. The first is the possibility of extending the implementation to the real time production and quality control. Another aspect is that SW tools for Mfg and functional modelling should have the features to be easy to use and expandable for product modelling and processes. This project comes from a need, and it has solved the issue in a simple and punctual way, giving to the researcher, quality and Mfg engineer the leverage to pre-design a manufacturing and quality process analysing any critical aspect of them and getting the most appropriate technical or managerial solution. When functional dryer model was developed in the QU4LITY project, it requested several months of work, now are just requested some weeks (it depends by the product and process complexity). Another important result is the integration of the functional model within the production process in perfect agreement with the ontological model. The MDO-E application is a starting point, not arrival point. It is conceptualized and developed to evolve, to be a modeler that allows to define the logical relations that must become operative, and it must be considered integrable into a wider and complex context. It means, the developed application model and its output can be integrable and integrated in the relational elements able to manage the production in real time, using a specific operational interfacing elements for collecting and processing the information.

Replication Potential

When the Data Structure will be changed to relational DB, the main potential replications could be: the development of production data structures, directly usable in the production and in the quality management systems. In particular considering the reconfigurable elements in according to the type of production, the type of product or the quality attributes that the manufacturing system must have. The data structure of the entities, defined by the ontology model, could represent a form of data standardization and normalization. If the MDO-E is considered as an editor of data structures, it could be interconnected to a system for collecting production data and quality measures. This is the way for managing and normalizing complex and heterogeneous elements of which the production systems are composed to a harmonic ontology schema. Another key evolving element, is the opportunity to integrate costs and timing related to the operations and processes modelled during the manufacturing design phase, giving to the developer constantly the status of the art if the target of timing and costing are under control or not.

Milan

Pilot Partners

Standards used

- Functional Modelling

- MPFQ

Digital Platforms & Tools

- Microsoft™ .Net

- Lasalle Technologies™: AddFlow

- Grapecity ™: Component One Studio Win Forms

Big Data Characterization

Data types

- QU4LITY DB

- TXT Files

Number of sources

- List of Appliance Components

- Mfg Operation List

- Mfg Process List

- Mfg Resource List

- Mfg Quality

- Product and Mfg Process Measures

Open data

No

Key Facts & KPIs

Productivity

PR1 – OEE 1,5%

PR2 – ASSEMBLY YELD (AY) 1,5%

PR2 – FIRST PASS YELD (FPY) 2,5%

Speed

SP1 – PRE MFG & QUALITY DESIGN 10%

Adoption Assessment

![]()

![]()

![]()

Technical feasibility

![]()

![]()

![]()

Economic feasibility

![]()

![]()

![]()

Replication potential