Part Quality Digital Twin Environment for GF Machining Solutions

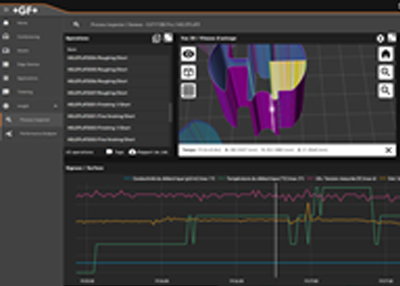

The new Digital infrastructure of GF Machining Solutions has gone live at EMO 2021 fair in Milano with the presentation of My rConnect, the digital HUB which delivers connectivity and analytics applications for GF devices using OPC UA standardised communication protocols. A specific application, the Process Inspector, has been developed for acquiring machine sensor data and analysing part and job information in a Digital Twin framework, aggregating relevant quality parameters and manufacturing data for enabling an advanced quality characterisation of the process and final part. The first analytical tools of this application help to identify potential deviations with respect to required quality KPIs and trace back the relevant process information in order to help quality assurance and optimisation processes of customers. The Qu4lity project has enabled the implementation of this particular framework and will provide in the future the advanced algorithms for automated qualification of parts, traceability and potential predictive maintenance measures in order to present defects during manufacturing processes with Milling machines.