Continental

Autonomous Quality in PCB Production for Future Mobility

Continental AG is a German based global Automotive Supplier. Main areas of activity are Safety and Motion, Architecture and Network, Smart Mobility, User Experience, Autonomous Mobility, Conti Tech and Rubber Products.

In 2021 Continental did 33,8 Billion sales supported by 190000 Employees in 527 sites in 58 countries.

Process Challenges

The automobile of the future will have increasingly self-driving features next to the electrification of road transport. In consequence this development triggers a strong shift towards highly reliable and often new electronic components and systems in the motor cars to come.

Volatile global markets with varying customer preferences and the demand for strict cost control set the corner stones, which are:

- achievement of highest product and system quality for very large lot sizes

- keeping close cost control in line with the OEMs cost ceilings

- remaining highly reactive regarding time-to-market, as well as volume-to-market For a PCB production site with an average manufacturing capacity of 30 to 40 million pcs per year quality, availability and efficiency are crucial.

Process Value

The production of automotive electronics for future mobility is based on automated lines that secure highest quality and output. For the production and assembly of respective PCBs an effective zero-defect approach and availability is paramount.

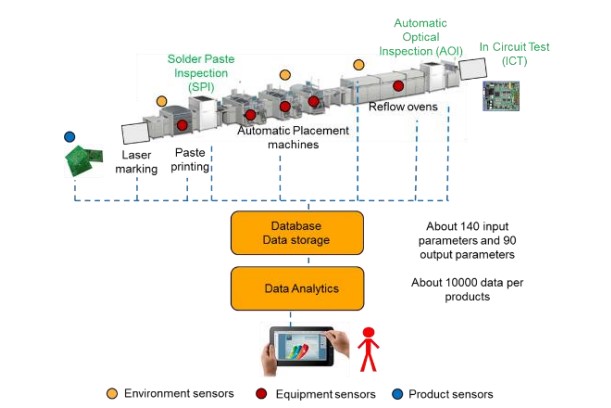

A single SMD line is used to assemble PCBs and Electronic components and follows a generic design. SMD line production consists of 4 different operations: Laser marking, paste printing, placement, reflow oven and three different inspections: Solder Paste Inspection, Automatic optical inspection, and In-circuit testing.

As shown in Fig. numerous sensors in combination with advanced data processing allows the control and operation of a single line with three operators, only. “Autonomus Quality” for a 1st Tier Automotive supplier is defined by:

- a single electronic PCB product regarding current and future mobility demands,

- an interactive SMD line

- the full production site.

Experiment Performance

ATB – SINTEF Contribution – Big Industrial Data Analytics and online Data Aquisition

- Identification of PCB customer returns as outliers using Sintef’s Principal Component Analysis and Mahalanobis Distance algorithms

- Filtering of Critical to Quality variables using domain expertise via the quality team at Sibiu, Romania

- Cooperation with ATB Bremen to create an operational automated solution for dataset extraction, preprocessing and formatting, analysis and results output to a graphical user interface inside Continental’s network

- Fully «white box» general solution sensitive to format, but not unit type, unique units or number of variables

Continental and Fraunhofer IAO collaborate on semantic search technology Introduction

- Continental team members at analysis stations have the permanent challenge to record failures in short time and match identified failures to a standard failure catalogue and past time failures.

- Fraunhofer IAO Semantic Search technology enables Search for corresponding Defect Name with user input based on a Defect Catalogue

PACE WEAVR supports reduction of human effort on the shopfloor

- Continental team members permanently have to do Training, Maintenance and Repair

- PACE provides technology using augmented reality for virtual assistance for these tasks

- Team members are freed up as the virtual assistance can take over routine tasks in Training, Maintenance and Repair

TUBS contribution

Problem Statement:

- Integration of new product variants leads to frequent pseudo errors, as “optimal” control limits (upper and lower) are unknown.

- Measuring needles of the ICT are wearing out and lead to failure and downtime of the inspection system.

Solution Approach:

- Development of a methodology for data-based analysis and modeling of the abrasion of individual measuring needles.

- With help of a visualization, the analysis and modeling results are made accessible to the user:

- Identification and presentation of trend analysis with regard to ICT measuring points towards upper or lower limits

- Visualization of the specific measuring needle on the adapter for quick identification and replacement

Value chain

Observations & Lessons learnt

BP1: Effort for Training was reduced significantly.

Trainers have more time now for Operational and Tactical activity on the shopfloor. Training can happen virtually to a large extent.

Through Change over and Maintenance there is less discussion and corrective action necessary. Preparation time for these activities went down to almost zero.

BP2: The possibility of early detection of defective parts by using statistical data analytics is proven! KPI PPM rate has a potential of 20% Reduction

BP3: Bad defect description can be avoided and high efforts for defect description are reduced by the technology. Response time for searches in the failure database is impressively low.

BP4: In the ICT area as well pseudo failures reduction and less time for Analyses can be observed.

Replication Potential

BP1: As this activity is executed as a pilot, Continental is planning to make use of the Technology to a larger extent in the future.

BP2: Continuation of cooperation is planned with or without funding.

BP3: Collaboration model needs to be further discussed.

BP4: Visual aids potential will be investigated in other areas in the future

Logistics Automotive Manager 2008 – 2012

Electronics Plants Manager 2012 – 2014

Plant Manger 2014 – 2016

IT Manager Manufacturing Applications since 2016

Continental | Sibiu, Romania

Pilot Partners

Standards used

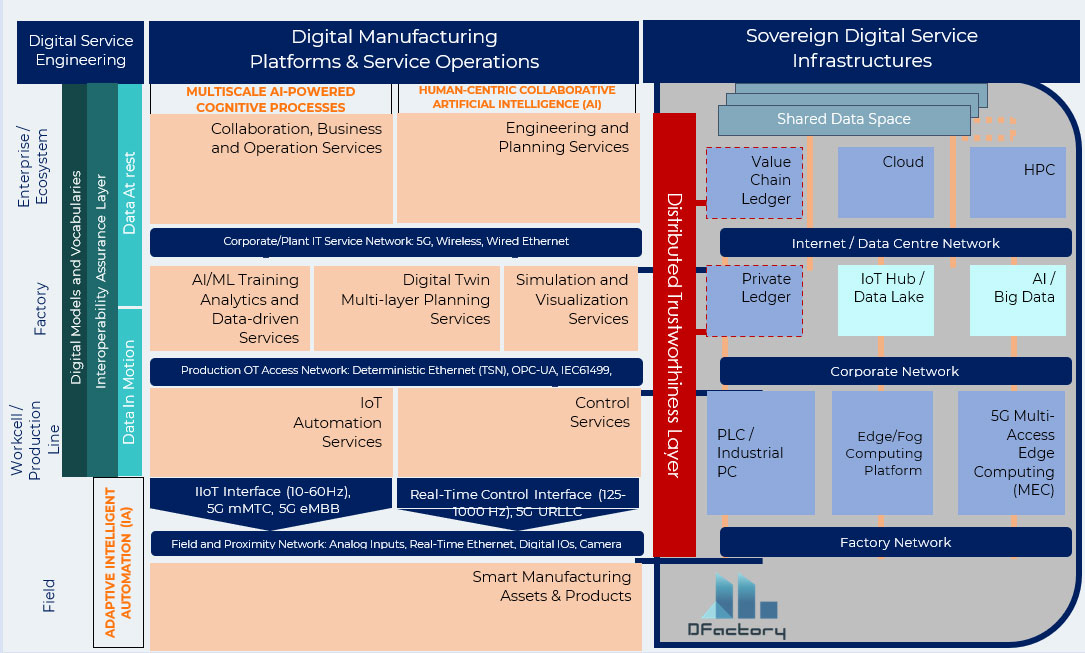

- MQTT

- OPCUA

- Kubernetes

- Docker

Big Data Platforms & Tools

- AWS

- Continental Manufacturing Data Lake

- Git Hub

Big Data Characterization

Data types

- Product characteristics

- Outliers

Number of sources

- Multiple Test stations

- Analytics stations

Open data

No

Key Facts & KPIs

Productivity

OEE – Overall Equipment Efficiency

FPY – First Pass Yield

Speed

MTTR – Mean time to repair

Time to analyse NOK tested Products

Sustainability

Scrap reduction

Agility

Time for Training of Production staff

Adoption Assessment

![]()

![]()

![]()

Technical feasibility

![]()

![]()

![]()

Economic feasibility

![]()

![]()

![]()

Replication potential